Image: Pankaj Varma and Julie Bose talking to Foundations students about their business experience of setting up a new brand called “Namo”, a series of Devotional Accessories as a design offering in the Indian marketplace.Learning about business processes and business models

Image: Pankaj Varma and Julie Bose talking to Foundations students about their business experience of setting up a new brand called “Namo”, a series of Devotional Accessories as a design offering in the Indian marketplace.Learning about business processes and business models has a two fold role in the making of a designer in India. The knowledge will hold them in good stead when they actually start practicing design and some of them will become entrepreneurs in their own right, by getting involved in start-up businesses using their design skills and entrepreneurial urge just as many of our graduates have done in the past. Many of such businesses have grown over the past ten or fifteen years and in my recent reflections in conversation with colleagues and students in the

DCC class at NID we have identified several classes of such businesses that have been set up by our young designers who have graduated from our institute. The second aspect of business is the understanding of the channel through which the design solutions developed during the design journey are delivered to the public in an extremely competitive space of the marketplace. Many a time great design solutions get sidelined due to some other factors that are usually beyond the control of the manufacturer, promoter or even the product creator. These could be factors in the legal space, the financial strategies employed or even in the layers of branding and positioning that may have been adopted by the marketing team. It is clear that even these offerings can be designed and explored to both reduce risk as well as to respond to current aspirations of users as well as conditions in the market that may call for a revision of the offering in line with the time and place in which it is being made.

Image: The Namo design collection launched by designer entrepreneurs Pankaj Verma and Julie BoseMaking of a design entrepreneur: Learning from peers

Image: The Namo design collection launched by designer entrepreneurs Pankaj Verma and Julie BoseMaking of a design entrepreneur: Learning from peersI have asked the Foundation students explore the field by contacting our graduates in the field in order to find role models for themselves to emulate when their time is ripe for action in the field. India has been a particularly hostile territory for young design aspirants since we have had a protected economy for so many years and design and the risk that it entails was far from the minds of the trader manufacturers who managed our industrial empires as well as the Government that was more interested in control through standards and laws and taxation and special privileges and subsidies rather innovation and market excellence. In my presentation at the

Conference on Design Support at Design Wales in 2004 I had the occasion to reflect on the Indian Design landscape and offer a number of categories for design businesses in India. This

conference paper (pdf 39kb) and

visual presentation (pdf 573kb) show the categories and these can be downloaded from my website at the links provided here. In order to give our students a framework to do their own research about their peers in the design business in India I offer a broad set of categories below which is in no way exhaustive but can give them a head start to look at this space and fill in the details for themselves as we go forward with their education.

Design schools and their curriculum has been focused on the creation of skilled personal for industry but many of our products, our graduates from the design programmes, end up being self employed and very happy indeed in that self appointed space. The journey may be traumatic for some or just as easy for others, but the lessons of the street food vendors that was explored by the DCC class would I am sure give our young aspiring designers some insights about how they too can survive in a hostile business environment which is not too supportive of design and the design activity in India has been just that over the past fifty years since the modern design movement started at Ahmedabad with the writing of the

Eames India Report in 1958 (pdf 359kb). Perhaps this has something to do with the nature of design itself and only time will tell. The National Design Policy too is perhaps barking up the wrong tree and trying to create designers to serve industry masters, but are they ready to listen? We need to look at other models where designers can work directly with people who need their support and the policy frameworks could be moulded to facilitate such a direction. Here I would draw the attention of my students to the experiments in the Northeast of England where the

Design Council UK has carried out the

DOTT07 initiatives with

John Thackara of

Doors of Perception fame as the design leader. Their book,

publications link and

online documentation pdf (5454kb) of this live one year long initiative is very exciting indeed and could be a model for decentralised design action in India as well. Design schools may need to reexamine their curriculum to ensure that entrepreneurship is included in their mandate and this may bode well for design profession in India going forward.

The broad categories that we identified for design action in India are listed below:

1. Design Consulting Offices (DCO’s) (a few names in each category)

Design Directions: Satish Gokhale and Falguni Patel (Product & Graphic Design)

Ray & Kesavan: Sujata Kesavan (Graphic Design & Branding)

Incubis: Amit Gulati and Sabyasachi Paldas (Product Design, Architecture and Branding)

Korjan Design Studio: Dinesh and Rashmi Korjan (Product Design)

Elephant Design: Sudhir Sharma and colleagues from NID (Graphic, Branding, Exhibition etc)

Idiom Design Studio: Sonia Manchanda, Jacob Mathew et al (Branding, Graphics, Retail)

Design Workshop: Devashis Bhattacharya (Graphics, Branding & Exhibitions)

Icarus Design: George Mathews (Product Design)

Whisper Design: Niladri Mukherjee (Product Design and Branding)

Lopez Design: Tony Lopez (Graphics, Branding)

Lokus Design: Chandrashekar Badve, Molond Risaildar & Siddharth Kabra (Design, Architecture and Branding)

2. Designer Producers (DPO’s)Quetzel: Sandeep Mukherjee and Sarita Fernandez (Furniture and Architectural Accessories)

Dovetail: Sunder S and John Mathew: (Furniture and Architectural Accessories)

Bodhi: Mala and Pradeep Sinha (Textile and Fashion products)

Designwise: Mukul Goel (Hand Crafted Metal artifacts and accessories)

Namo: Pankaj Verma and Julie Bose (Devotional Accessories)

Curiosity Workshop: Mala and Bela Shodhan (Soft Toys and Furnishings)

3. Designer Producer with Retail outlets (DPR’s)Abraham & Thakore: David Abraham and Rakesh Thakore (Textile and Fashion products)

Tulsi: Neeru Kumar (Textile and Home Furnishing)

Bandhej: Archana Shah (Textile, Fashion and Accessories)

The Design Store: S Sunder, John Matthew, Jacob Matthew & Anand Aurora (Furniture & Accessories)

4. Interior Design and Exhibit Design services (IED’s)Design Habit: Amardeep Behl: (Exhibition Design)

Design Core & Design Laboratory: Vikram Sardesai and Surya Gowda (Exhibition Design)

5. Design Research Services (DRS’s)Onio Design: Mahoj Kotari (Product Design and Trend Research)

Variations Art Gallery & Freedom Tree Design: Latika Puri Khosla (Colour Research Services)

Sonic Rim: Uday Dandavate (People oriented Trend Research)

6. Design Led Institutions / NGO Activists (DLI’s)Riverside School: Kiran Bir Sethi (Primary and Secondary School)

Khumbam: K B Jinan (Craft Based Production of Terracota Murals)

Industree: Neelam Chibber

(Grass based village and artisanal initiatives)Daily Dump: Poonam Bir Kasturi (Organic Waste management system)

Vikalp Design: Laxmi Murthy (Communication for Rural Health)

7.Interaction and Interface Design (IID’s)Codesign: Rajesh Dahiya (Interface Design and Graphics)

Edot Solutions: Sanjay Sarkar (Information Design Software)

8. Corporate Design Intrapreneurs (CDI’s)Atmosphere & Himatsingka Design Studio: Jayshree Poddar (Silk Furnishing)

I am sure that we can think of many more such initiatives and see that these are not exhaustive in any way. However, with the creation of the Design Business Incubation Centre at NID with support from the DST perhaps more alternatives will be explored in the days ahead. Perhaps the practicing designers in India can share their experiences and disclose closely held business strategies to design students so that it would encourage several of them to think of taking the entrepreneurial route when the time is right. Data on their business turnover and what they do and how they operate is rarely available since the whole area of design journalism is so poorly operated and structured in India today. I hope that this too will change in the days ahead.

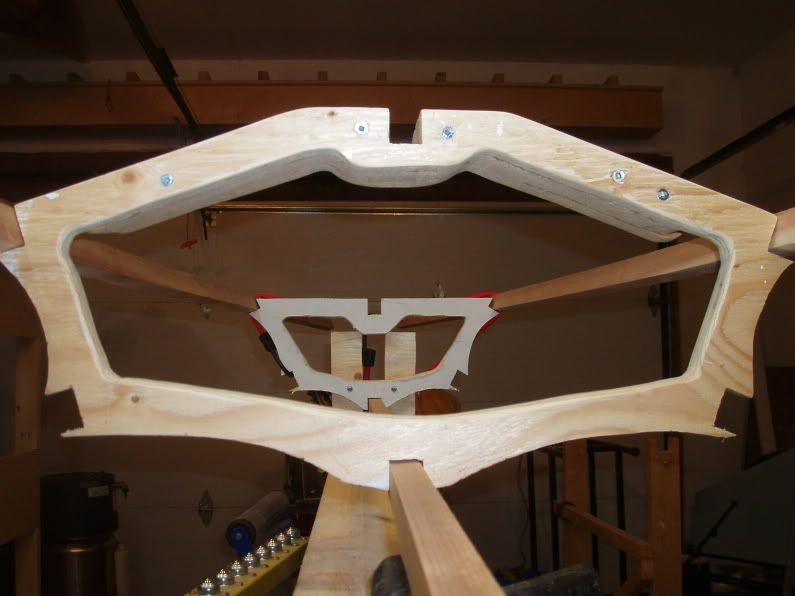

The fore deck stringer was notched to better fit into the groove in the top of the masik.

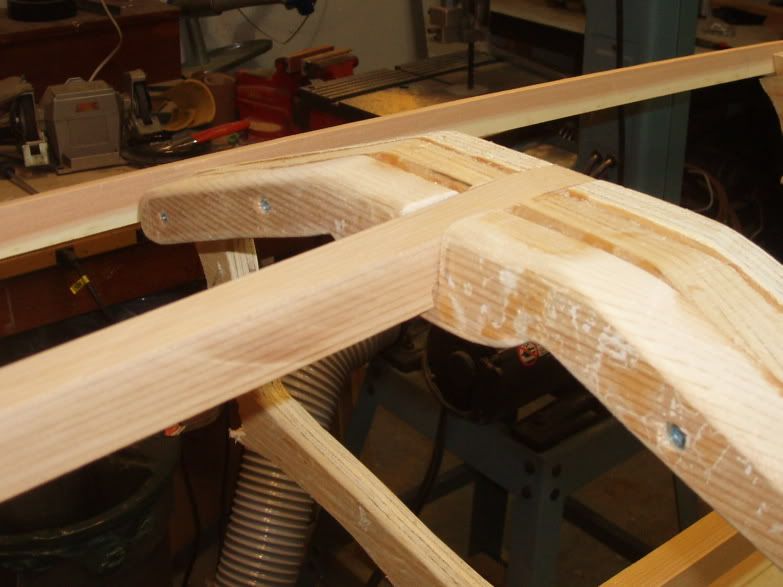

The fore deck stringer was notched to better fit into the groove in the top of the masik. The masik and the rest of cross section #2 has had all edges rounded off and sanded smooth. The paddler's legs project through the opening in this cross section so it needs to be smooth & comfortable.

The masik and the rest of cross section #2 has had all edges rounded off and sanded smooth. The paddler's legs project through the opening in this cross section so it needs to be smooth & comfortable.